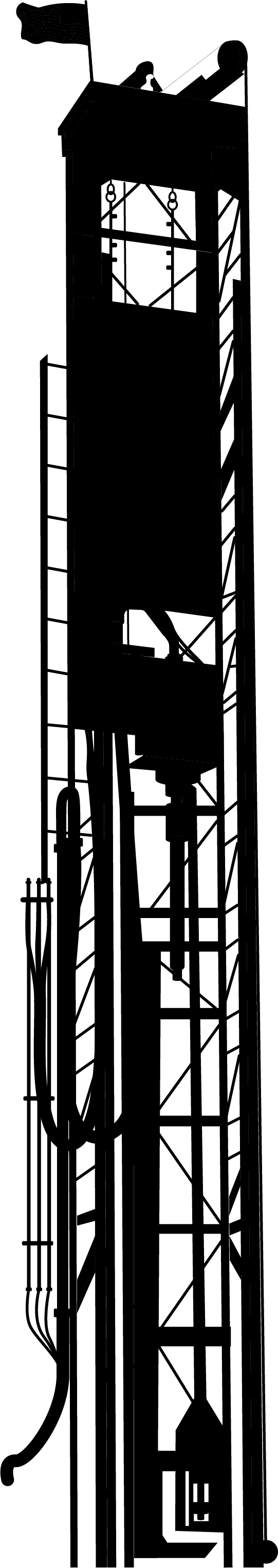

Our Business is

SERVING THE DRILLING INDUSTRY

Looking for a reliable water well drilling tool fabricator? Our expertise in manufacturing high-quality drilling tools ensures efficient and precise well construction. Explore our fabrication services for a wide range of tools designed to meet your drilling needs. Contact us today for expert advice and top-notch drilling solutions. Located in Bakersfield, CA. in the heart of Kern County. We service rigs all over the central valley and California.

Tool Fabrication

Tricone Bit Refurbishment:

• Disassembly, inspection, and welding repair of tricone bits to extend their lifespan and optimize performance.

Custom Tricone Bit Manufacturing:

• Designing and fabricating custom tricone bits tailored to specific geological conditions or drilling requirements.

Hole Opener Modification:

• Welding modifications to hole openers for size adjustments, improved durability, or compatibility with different drilling conditions.

Drag Bit Repair and Maintenance:

• Welding and refurbishing drag bits, including re-sharpening of cutting elements and replacing worn-out components.

Bit Lifter Fabrication:

• Designing and manufacturing custom bit lifters to assist in the safe removal and installation of tricone bits.

Bit Breaker Services:

• Welding and repairing bit breakers used to break the connection between the drill bit and the drill pipe during tripping operations.

Rebuilding Bearing Sections:

• Specialized welding to rebuild and strengthen the bearing sections of tricone bits, ensuring reliable performance.

Hardfacing Application:

• Applying hardfacing materials to increase the hardness and wear resistance of critical bit components.

Gauge Protection Welding:

• Welding additional protection onto the gauge areas of tricone bits to prevent premature wear.

Stabilizer Modification:

• Welding modifications to stabilizers for enhanced drilling stability and performance.

Bit Inspection Services:

• Conducting thorough inspections of tricone bits and other drilling tools to identify potential issues and recommend necessary repairs.

Custom Tool Design and Fabrication:

• Designing and fabricating specialized drilling tools based on unique client specifications or challenging drilling conditions.

Cutter Replacement:

• Removing and replacing worn or damaged cutters on tricone bits to maintain optimal cutting efficiency.

Field Services:

• Providing on-site welding and fabrication services for drilling tools, reducing downtime and ensuring quick repairs.

Quality Control and Testing:

• Implementing quality control measures and testing procedures to guarantee the integrity and performance of fabricated tools.

Material Upgrades:

• Upgrading tool components with advanced materials to improve strength, durability, and resistance to wear and corrosion.

Technical Consultation:

• Offering expert advice on tool selection, modifications, and maintenance to optimize drilling operations.

<h5 style="text-align: center;">Delivery and Hotshots Available</h5>

Rig Welding

Well Casing Repair:

• MIG, TIG, or Stick welding can be used to repair cracks or breaks in the well casing, ensuring structural integrity.

Casing Extensions:

• Welding extensions onto the well casing for deepening the well or adjusting to changes in the water table.

Casing Reinforcement:

• Reinforcing weak points in the well casing with additional metal, improving overall strength and durability.

Pump Mounting and Repairs:

• Fabricating and welding mounts for well pumps, as well as repairing existing mounts.

Well Cap Fabrication:

• Creating or repairing well caps using appropriate welding techniques for a secure and watertight seal.

Flange Welding:

• Welding flanges onto the well casing or pipes for easy connection and disconnection during maintenance or repairs.

Piping Installation and Repairs:

• Welding pipes together for the water supply system, as well as repairing any leaks or damaged sections.

Wellhead Welding:

• Welding and repairing the wellhead structure to maintain its integrity and prevent contamination.

Pressure Tank Welding:

• Fabricating and welding brackets or supports for pressure tanks associated with the well system.

Custom Fabrication:

• Designing and welding custom components for unique well configurations or specific client requirements.

Corrosion Repair:

• Welding to repair or reinforce areas of the well casing or components affected by corrosion.

Emergency Repairs:

• Providing on-site emergency welding services for sudden issues that may affect the well’s performance.

Welding Inspections:

• Conducting regular inspections to identify potential welding issues and performing preventive maintenance.

Welding Consultation:

• Offering expertise and advice on the best welding practices and materials for specific well applications.

Material Upgrades:

• Upgrading well components with stronger or more corrosion-resistant materials to extend the well’s lifespan.

Other Welding

Truck Equipment and Flat Beds:

• Removal and repair of work truck components and tools. Fabrication services for flat bed, installation or repair. We get your service and fleet trucks operational and back on the road.

All other Welding and Fabrication:

• We provide a special service for general welding and fabrication projects. If you have one off projects that need repair, call today!